The look on the faces reminds me of my days working in a plating factory. It was damp, cold in the winter and hotter then hell in the summer, not a lot to smile about. If you are familiar with Indiana summers and winters and consider the factory environment (no a/c and primitive heating systems of 1911) , well what more can i say. I have included a few more photographs from my collection.

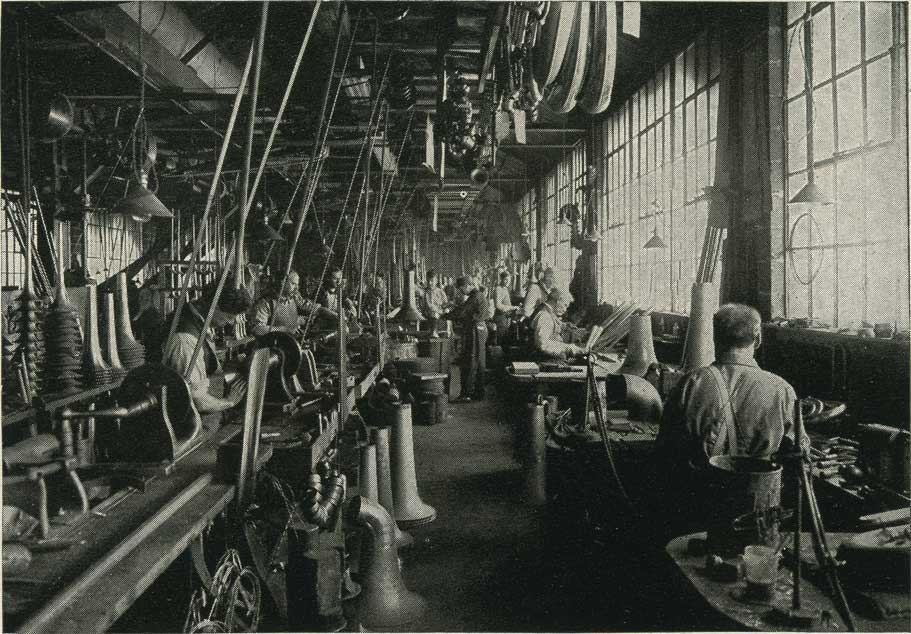

Belt driven polishing lathes are a bit before my time but I did work in a silver-smithing shop that had rotary hammers and hand operated drop forges that were belt driven. Those were machines that could rattle the teeth out of your skull. At least the friction of polishing brass creates heat that is very welcome in the winter months, I can't say that about the summer.

The draw bench department is where the tubes are formed on mandrels as they are pulled trough steel dies or thick rings made of lead. This is where large branches, bell stems (prior to bending) and tuning slide tubes are made along with many other tube parts.

The engraving department was the bottle-neck in the Conn factory until the new owners in the late teens substantially reduced the number of patterns and amount of work put on there instruments.

Messy work but man did they do good, durable plating.

Valve department, lots of little parts to assemble

The place where all those little parts are made.

Daniel C. Oberloh

Oberloh Woodwind and Brass Works

Saving the world, one horn at a time...