When I got it, the tube before the bottom bow and about 2 inches of the bottom bow was flattened about half way in. The upper bow had some pretty nasty dents. The bell had some huge dents in the flare and an even bigger (5x5 inch) dent immediatly above the leadpipe.

I have taken off the leadpipe, bottom bow, and bell, taken out the dents to the best of my ability, and just put it back together except the braces will be another day. Also the water keys don't have cork yet

It plays great and will be a much better practice tuba than I was expected since I payed only $120 for it.

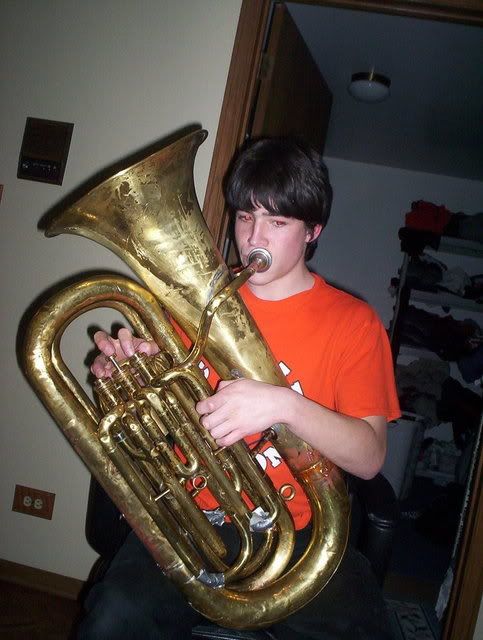

^Me Tubaing after playing repair man^