Martin Top-Action 4 Rotor

Posted: Sun Nov 06, 2011 4:32 pm

Hi everyone,

I've had lots of questions about this horn since I bought it on eBay. Kiltietuba and Hattuba suggested I start a post on this unusual horn so that people that have had the chance to see it and play it can post their observations and opinions. I've been wanting to post some more/better shots of the horn but whenever I have a few spare minutes to take gome good pictures outside its either dark out or raining. I'll get this posting started with the eBay pic's then will add new pic's as I can.

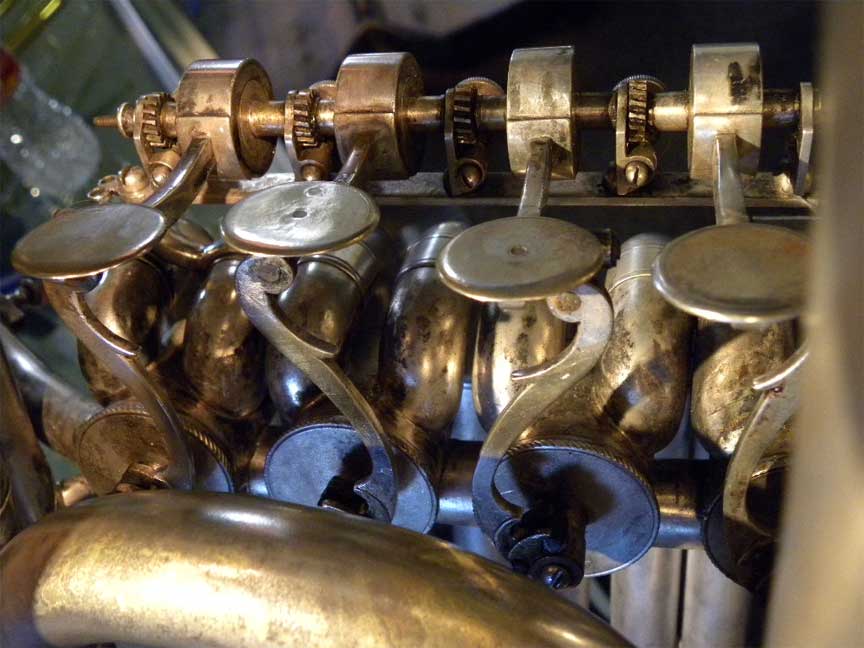

I was picking up another horn after some repairs at Oberloh Woodwind & Brassworks a couple weeks ago. Daniel Oberloh said he'd like to see the Martin and Kiltietuba said be interested in seeing the horn and he'd bring along his jumbo sousaphones for me to drool on. Daniel felt that the horn had probably gone thru a "Factory" reconditioning program at sometime in it's past. Once upon a time Conn and other big production manufacturers would recondition any horn that came thru their doors. Daniel said that lots of older horns we're fixed up during the war since the manufacture of new brass instrumnets was not a priority. The horn's finish is satin silver but Daniel felt that the horn had bright silver accents on it when it was new. There is evidence of repair work in the top & bottom bows. The work is decent but Daniel pointed out that the work was probably done before the advent of the modern dent removal tools so there are still areas where you can see and feel where the metal was worked. Daniel commented on the engraving on the bell. The overall size of the logo is large but the engraving itself is very plain and simple, much less ornate the the York's and King's of the same era. We removed the linkage from the #3 valve, removed the cap, and then the valve. I'm guessing the valves are brass from their brownish color and they are hollow, not solid. Daniel said the valves and bearings aren't in bad shape considering the age of the horn but he felt there was plenty of room for improvement if the horn was being restored. Another area that could use attention was the bow caps. There are a few stress cracks present in the bow caps that are probably due to the horn being blasted prior to being refinished. Sandblasting causes the metal to expand and contract and since the cap won't shrink & grow at the same rate as the metal underneith a crack can occur. A new set of caps will be added if I ever have this horn restored. Daniel said the tube size is .716. The bell diameter is 20".

Daniel and Kiltietuba both played the horn and made some nice sounds with it. Paul, who works for Oberloh's, also played the horn and had a smile on his face when he put it down. I'll leave it up to these guys to post their opinions. I requested that they be frank about their feelings on the horn. I like the low range on this horn but this was one area on the horn that all three players thought was weak. Everyone felt this horn's strongest area is in the mid-range. The add on eBay gave the year of the horn as 1920. Daniel had a list of Martin serial numbers starting in 1917. By averaging the number of horns Marting produced from 1917 forward we're guessing that this horn was produced between 1912 and 1914. I plan on having the horn restored eventually but I'm enjoying the patina it has far too much to be in any hurry to have this one taken apart

I've had lots of questions about this horn since I bought it on eBay. Kiltietuba and Hattuba suggested I start a post on this unusual horn so that people that have had the chance to see it and play it can post their observations and opinions. I've been wanting to post some more/better shots of the horn but whenever I have a few spare minutes to take gome good pictures outside its either dark out or raining. I'll get this posting started with the eBay pic's then will add new pic's as I can.

I was picking up another horn after some repairs at Oberloh Woodwind & Brassworks a couple weeks ago. Daniel Oberloh said he'd like to see the Martin and Kiltietuba said be interested in seeing the horn and he'd bring along his jumbo sousaphones for me to drool on. Daniel felt that the horn had probably gone thru a "Factory" reconditioning program at sometime in it's past. Once upon a time Conn and other big production manufacturers would recondition any horn that came thru their doors. Daniel said that lots of older horns we're fixed up during the war since the manufacture of new brass instrumnets was not a priority. The horn's finish is satin silver but Daniel felt that the horn had bright silver accents on it when it was new. There is evidence of repair work in the top & bottom bows. The work is decent but Daniel pointed out that the work was probably done before the advent of the modern dent removal tools so there are still areas where you can see and feel where the metal was worked. Daniel commented on the engraving on the bell. The overall size of the logo is large but the engraving itself is very plain and simple, much less ornate the the York's and King's of the same era. We removed the linkage from the #3 valve, removed the cap, and then the valve. I'm guessing the valves are brass from their brownish color and they are hollow, not solid. Daniel said the valves and bearings aren't in bad shape considering the age of the horn but he felt there was plenty of room for improvement if the horn was being restored. Another area that could use attention was the bow caps. There are a few stress cracks present in the bow caps that are probably due to the horn being blasted prior to being refinished. Sandblasting causes the metal to expand and contract and since the cap won't shrink & grow at the same rate as the metal underneith a crack can occur. A new set of caps will be added if I ever have this horn restored. Daniel said the tube size is .716. The bell diameter is 20".

Daniel and Kiltietuba both played the horn and made some nice sounds with it. Paul, who works for Oberloh's, also played the horn and had a smile on his face when he put it down. I'll leave it up to these guys to post their opinions. I requested that they be frank about their feelings on the horn. I like the low range on this horn but this was one area on the horn that all three players thought was weak. Everyone felt this horn's strongest area is in the mid-range. The add on eBay gave the year of the horn as 1920. Daniel had a list of Martin serial numbers starting in 1917. By averaging the number of horns Marting produced from 1917 forward we're guessing that this horn was produced between 1912 and 1914. I plan on having the horn restored eventually but I'm enjoying the patina it has far too much to be in any hurry to have this one taken apart