Page 1 of 1

Conn factory images

Posted: Fri Jan 14, 2005 12:46 am

by Daniel C. Oberloh

I was going over some of my old band instrument catalogs for another post and while admiring some of the old factory shop photographs, got to thinking about the older horns and how much work it was back then to make brass instruments. I soon snapped back to reality and realized even though technology has advanced the design of band instruments and machines have been invented that allow the builder to do things they could not have imagined a century ago, it is still very hard work to build tubas and even harder to rebuild them.

I thought I would share a few of those images and hope that we can all take the time and think about the skill it took so log ago to dream up and build these works of art that we all gain so much pleasure from.

The images are from C.G. Conn's Elkhart factory c 1911. I have more where this came from. Let me know if you would like me to post them. I am working on my computer skills and this is a good exercise for me.

Its amazing that I am able to rebild horns and make them look so nice but find that unlike myself, my 10 and 11 year old Nephews can opperate a computer with minimal effort.

I hope you all enjoy te photographs.

Daniel C. Oberloh

Oberloh Woodwind and Brass Works

Saving the world, one horn at a time...

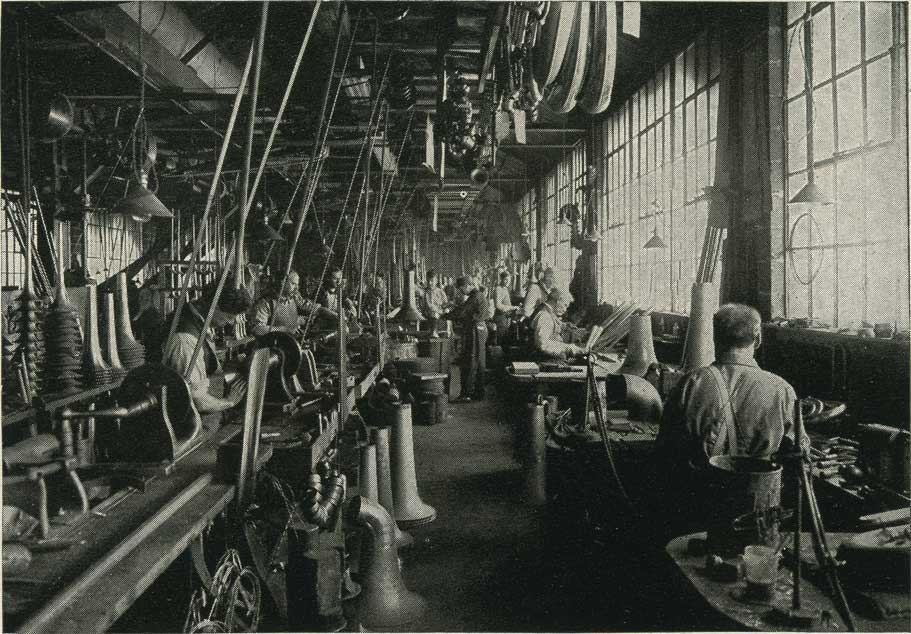

The bell spinning department.

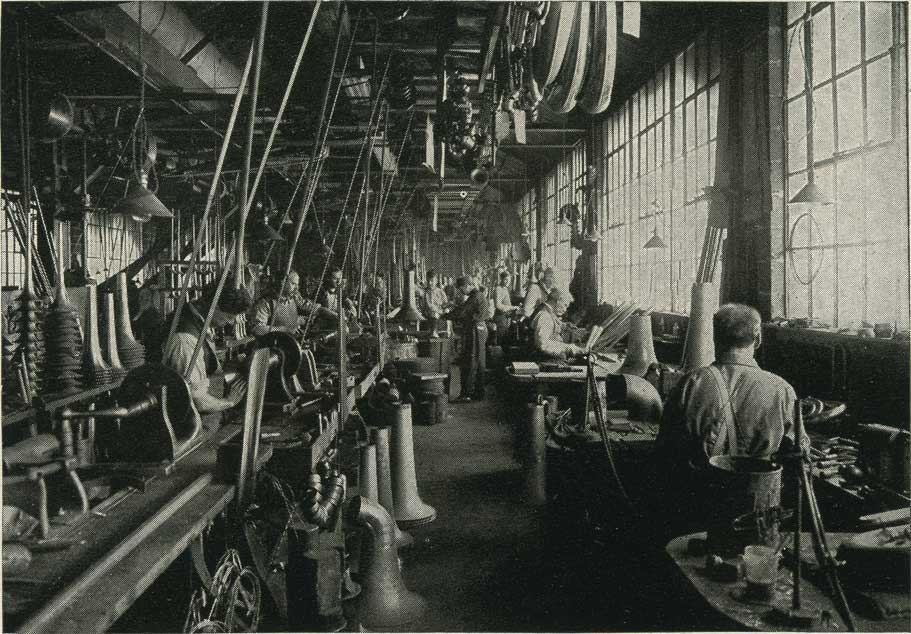

The mounting department.

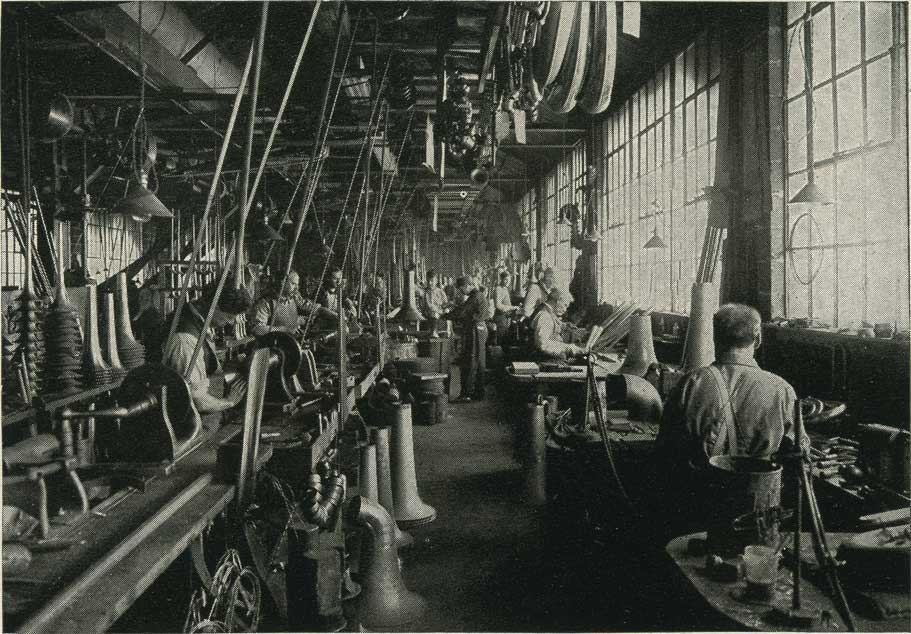

Helicon bending Dept?!!

Posted: Fri Jan 14, 2005 4:59 am

by JayW

would it be safe to say " They dont build'em like that anymore!" ?

Posted: Fri Jan 14, 2005 5:13 am

by UDELBR

JayW wrote:would it be safe to say " They dont build'em like that anymore!" ?

Dunno. Aside from the overhead pulleys used to convey power to machinery, the instrument factories I've visited in Germany look quite similar, right down to the bow-bending lever.

Great photos, Dan! More! More!!

Posted: Fri Jan 14, 2005 8:33 am

by TonyZ

I absolutely love the looks on their faces at the bow bending lever! That's concentration, or deep meditation. Great photos!

Posted: Fri Jan 14, 2005 5:07 pm

by Daniel C. Oberloh

The look on the faces reminds me of my days working in a plating factory. It was damp, cold in the winter and hotter then hell in the summer, not a lot to smile about. If you are familiar with Indiana summers and winters and consider the factory environment (no a/c and primitive heating systems of 1911) , well what more can i say. I have included a few more photographs from my collection.

Belt driven polishing lathes are a bit before my time but I did work in a silver-smithing shop that had rotary hammers and hand operated drop forges that were belt driven. Those were machines that could rattle the teeth out of your skull. At least the friction of polishing brass creates heat that is very welcome in the winter months, I can't say that about the summer.

The draw bench department is where the tubes are formed on mandrels as they are pulled trough steel dies or thick rings made of lead. This is where large branches, bell stems (prior to bending) and tuning slide tubes are made along with many other tube parts.

The engraving department was the bottle-neck in the Conn factory until the new owners in the late teens substantially reduced the number of patterns and amount of work put on there instruments.

Messy work but man did they do good, durable plating.

Valve department, lots of little parts to assemble

The place where all those little parts are made.

Daniel C. Oberloh

Oberloh Woodwind and Brass Works

Saving the world, one horn at a time...

Posted: Fri Jan 14, 2005 8:20 pm

by Daniel C. Oberloh

The look on the faces reminds me of my days working in a plating factory. It was damp, cold in the winter and hotter then hell in the summer, not a lot to smile about. If you are familiar with Indiana summers and winters and consider the factory environment (no a/c and primitive heating systems of 1911) , well what more can i say. I have included a few more photographs from my collection.

Belt driven polishing lathes are a bit before my time but I did work in a silver-smithing shop that had rotary hammers and hand operated drop forges that were belt driven. Those were machines that could rattle the teeth out of your skull. At least the friction of polishing brass creates heat that is very welcome in the winter months, I can't say that about the summer.

The draw bench department is where the tubes are formed on mandrels as they are pulled trough steel dies or thick rings made of lead. This is where large branches, bell stems (prior to bending) and tuning slide tubes are made along with many other tube parts.

The engraving department was the bottle-neck in the Conn factory until the new owners in the late teens substantially reduced the number of patterns and amount of work put on there instruments.

Messy work but man did they do good, durable plating.

Valve department, lots of little parts to assemble

The place where all those little parts are made.

Daniel C. Oberloh

Oberloh Woodwind and Brass Works

Saving the world, one horn at a time...

Posted: Sat Jan 15, 2005 12:43 am

by jacobg

Great Pictures.

I have a 1910 Conn Eb which was black with dirt and tarnish when I got it. Underneath it miraculously had about 90% of the silver intact.

Does anyone have any idea of the volume that they would produce horns? For instance, how many top-of-the-line 4 valve BBb tubas would they produce in a year like 1925 or 1930? From what I've heard, Conn was the largest instrument company in the world at this period. Would they have enough volume on big horns to have one worker who specialized in making only one model, or did all the workers do many different models (or even different instruments) and find themselves working on the same model only every few months? From these pictures it would appear that, on a large complicated horn, there were many, many different workers involved, and the entire instrument and all of its parts from start to finish might take months to fabricate (they probably kept things like valves in stock, right?).

Sorry for all the questions. I've always been curious about when someone says something like "20's Conn 32J's are great horns", because if the manufacturing process is so complex and involves so many people over so many months, and one particular model is only produced every few weeks (or months) wouldn't each horn vary vastly in the way it played?

Its amazing that I am able to rebild horns and make them look so nice but find that unlike myself, my 10 and 11 year old Nephews can opperate a computer with minimal effort.

Its amazing that I am able to rebild horns and make them look so nice but find that unlike myself, my 10 and 11 year old Nephews can opperate a computer with minimal effort.  I hope you all enjoy te photographs.

I hope you all enjoy te photographs.