Page 1 of 3

Re: Playing with Plexiglas

Posted: Sat May 17, 2008 9:49 pm

by windshieldbug

Make yourself a backstop between yourself and the tympani and save your own ears!

Re: Playing with Plexiglas

Posted: Sat May 17, 2008 10:11 pm

by SplatterTone

Weld up some mighty tough multi-pane windows, maybe a french door.

Re: Playing with Plexiglas

Posted: Sat May 17, 2008 10:32 pm

by TubaRay

That's some cool stuff, Wayne. I especially like the swing.

Re: Playing with Plexiglas

Posted: Sun May 18, 2008 12:07 am

by willbrett

After you sand those edges down with the 1500 grit paper (and I strongly recommend wet-sanding them with some automotive grade wet-sanding paper), try hitting the sanded surfaces with a high speed buffer and some mildly abrasive buffing compound. You should be able to get them nearly perfectly transparent.

I use this same technique to polish out yellowed car headlights, and it works like a charm.

FWIW,

-Brett

Re: Playing with Plexiglas

Posted: Sun May 18, 2008 12:49 am

by The Big Ben

willbrett wrote:After you sand those edges down with the 1500 grit paper (and I strongly recommend wet-sanding them with some automotive grade wet-sanding paper), try hitting the sanded surfaces with a high speed buffer and some mildly abrasive buffing compound. You should be able to get them nearly perfectly transparent.

It has been my experience that the easiest way to get a rough Plexiglass edge smooth is to use a propane torch on it. I learned this from a very experienced commercial Plastics fabricator whose company mainly made retail displays.

Get the edge the shape you want it and go as fine as 220 grit paper. Use a torch with a wide flame (a paint removal nozzle is good) and just move the torch over the finish until it is as smooth as you want it. Watch what you are doing and fan the heat over the edge so that you can barely see a change with every pass. Move it quickly. You don't want to burn it.

If you don't believe me, give it a try on a piece of material. You have nothing to lose because your supply is so large. If you want to use the smoother grades of paper and then finally a buffer, go at it. If that's what gives you the edge you want, it's your project. You can save a lot of time by using a torch. Give it a try.

Re: Playing with Plexiglas

Posted: Sun May 18, 2008 3:40 pm

by ken k

Very cool ideas.

I use a sheet of plexiglas on my music stand at outdoor concerts to keep my music from blowing away (obviously not 1 1/2" think however)

ken k

Re: Playing with Plexiglas

Posted: Sun May 18, 2008 6:09 pm

by ken k

schlepporello wrote:I managed to grab a few thinner pieces of scrap simply for that purpose. Not that I'd ever use them myself, as I have another solution to that. But some of my fellow musicians could surely benefit from the thinner pieces. The only problem I have with these thinner pieces other than them not being bullet resistant is the fact that they still have the protective paper on both sides. I don't know if they are clear or tinted.

Do you feel you need bulletproof glass when you play???

You could make a "Schleppmobile" similar to the "popemobile"

Just who do you play for???

k

Re: Playing with Plexiglas

Posted: Sun May 18, 2008 9:47 pm

by Tubaryan12

Will the Super glue hold it?

Yes, but it may not be the best choice over the long run. Super glues work best on small area, closely fitting parts. These type of adhesives also generate a good deal of heat during cure when large amounts are used (I know...I burned a hole in a shirt at work

). If it does work, the bond will be brittle and break easily with shock. There should be better ways to do this either with a chemical type bond or possibly using a clear epoxy.

For security, some type of mechanical fastener should always be used with larger projects using multiple pieces. Plexiglass dowls would be cool. Small metal ones with the plastic welding would be even better.

If the base in interlocking ( " X " shaped) no glue would be needed at all. Just Make the base with the interlocking parts and then drop the table top on it with silicone rubber discs to prevent slipping.

Re: Playing with Plexiglas

Posted: Sun May 18, 2008 10:58 pm

by SplatterTone

Re: Playing with Plexiglas

Posted: Mon May 19, 2008 1:06 am

by tubatooter1940

I have plexiglass ports (windows) in my boat and I hate the way plexiglass gets so scratched so easily.

I had a lexan (tinted) overhead hatch on the boat that was damaged so badly it had to be replaced.

Eastern Shore Glass had lexan in the tint I wanted. For the price of material, They used my old hatch as a pattern and cut the new lexan hatch perfectly to shape for me and drilled all new holes just the right size, in just the right places to attach all necessary hardware. I love those guys!

Re: Playing with Plexiglas

Posted: Mon May 19, 2008 1:22 am

by BriceT

I really like the plexiglas swing. Very neat!

Re: Playing with Plexiglas

Posted: Mon May 19, 2008 1:24 am

by willbrett

Because I do it every day...

I'm telling you, scratches in Plexiglas can be fixed in just a few minutes... a little bit of wet sanding, and some high speed buffing is all it takes. Chrysler and Volkswagen headlights are the worst.

(And I own one of each)

-Brett

Re: Playing with Plexiglas

Posted: Mon May 19, 2008 1:28 am

by Todd S. Malicoate

willbrett wrote:Chrysler and Volkswagen headlights are the worst.

I don't understand the reference...composite type automotive headlights (the ones with the replaceable bulb in the back) are nearly all composed of polycarbonate plastic, not Plexiglas.

Todd S. "who sells them every day" Malicoate

Re: Playing with Plexiglas

Posted: Mon May 19, 2008 2:32 am

by willbrett

Todd S. Malicoate wrote:willbrett wrote:Chrysler and Volkswagen headlights are the worst.

I don't understand the reference...composite type automotive headlights (the ones with the replaceable bulb in the back) are nearly all composed of polycarbonate plastic, not Plexiglas.

Todd S. "who sells them every day" Malicoate

With no intentions of starting any sort of argument here, and I usually feel that Mr. Malicoate is 100% correct, and many times says things that I feel like writing, but am too chicken to write...

I've found both the "lexan" lenses that car manufactures claim to have installed on their vehicles (supposedly rock/chip/crack/breakage proof) and regular old plexiglas to behave similarly while I'm trying to remove scratches/imperfections from them. I service auto dealerships daily, repairing paint blemishes, scuffs, scrapes, chips, painting bumpers, painting quarter panels/doors/hoods, as well as repairing yellowed, dried, and cracked headlights. I've also used 1/4 - 3/8" plexiglas as replacements in houses that I've owned (usually with window unit air conditioner sized holes being cut into them)... I'm the first to admit that I've got no experience with the thickness of the glas being discussed in this thread, but I believe that the same principals hold true. If the plexiglas is scratched/blury/yellowed/weathered, it can be sanded and polished back to *nearly* it's original sheen.

Re: Playing with Plexiglas

Posted: Mon May 19, 2008 2:49 am

by Todd S. Malicoate

Well said. You are absolutely correct...the "headlight restoration" kits that we sell at Napa even say on the package that they also work on Plexiglas and acrylics...the materials are very similar. I just thought you were saying the headlights on Chryslers and Volkswagens are made of Plexiglas. People often ask when pricing a headlamp assembly why they are so expensive...my stock "script" for such a situation includes an explanation of the space-age, expensive material known as polycarbonate (PC) plastic.

Todd S. "also not wanting to argue, but unable to sleep" Malicoate

Re: Playing with Plexiglas

Posted: Mon May 19, 2008 3:02 am

by willbrett

Todd S. Malicoate wrote:Well said. You are absolutely correct...the "headlight restoration" kits that we sell at Napa even say on the package that they also work on Plexiglas and acrylics...the materials are very similar. I just thought you were saying the headlights on Chryslers and Volkswagens are made of Plexiglas. People often ask when pricing a headlamp assembly why they are so expensive...my stock "script" for such a situation includes an explanation of the space-age, expensive material known as polycarbonate (PC) plastic.

Todd S. "also not wanting to argue, but unable to sleep" Malicoate

Ah, yes... I spent almost 3 years of my life (which I'll never get back) selling cars. One part of our 'scripted' sales pitch described the amazing toughness of the space-age polycarbonate (we called them lexan, and I'm not sure of the difference) plastic headlights. We actually had to bang on them with our knuckles as hard as we could... just to show how 'tough' they are. Of course these have been required of all manufacturers since sometime in the late 90's, but even in 2008, you'll hear salesmen telling you that they're one reason that their brand of car is the "best".

It's a good thing this thread is already in the "off topic" section, isn't it?

Re: Playing with Plexiglas

Posted: Sun Jun 01, 2008 1:20 am

by Dave Hayami

Hey Schlep,

When are you going to cut a blank and turn out your own mouthpiece?

Dave Hayami

Re: Playing with Plexiglas

Posted: Sun Jun 01, 2008 8:03 am

by dwaskew

schlepporello wrote:

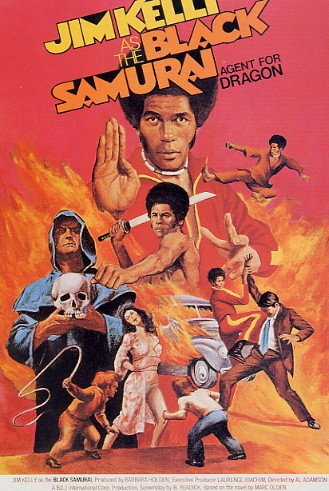

I don't think I'd do near as good a job as Jim Kelly.

I had no idea he made those mouthpieces......!

Re: Playing with Plexiglas

Posted: Sun Jun 01, 2008 10:38 am

by The Jackson

dwaskew wrote:schlepporello wrote:

I don't think I'd do near as good a job as Jim Kelly.

I had no idea he made those mouthpieces......!

Excuse me, sir, but I believe you have the incorrect "Jim Kelly"...

Re: Playing with Plexiglas

Posted: Sun Jun 01, 2008 11:03 am

by ThomasDodd

willbrett wrote:the space-age polycarbonate (we called them lexan, and I'm not sure of the difference) plastic headlights.

Lexan is a brand name of polycarbonate resin thermoplastic.

Calibre, Makrolon, and Panlite are other brand names.

http://en.wikipedia.org/wiki/Lexan

http://en.wikipedia.org/wiki/Polycarbonate

Schlep, cool stuff. Great that you have access to the "scraps" too. Use it just about anywhere you'd use wood or steel. Stronger and more durable than wood, and easier to work with than steel.