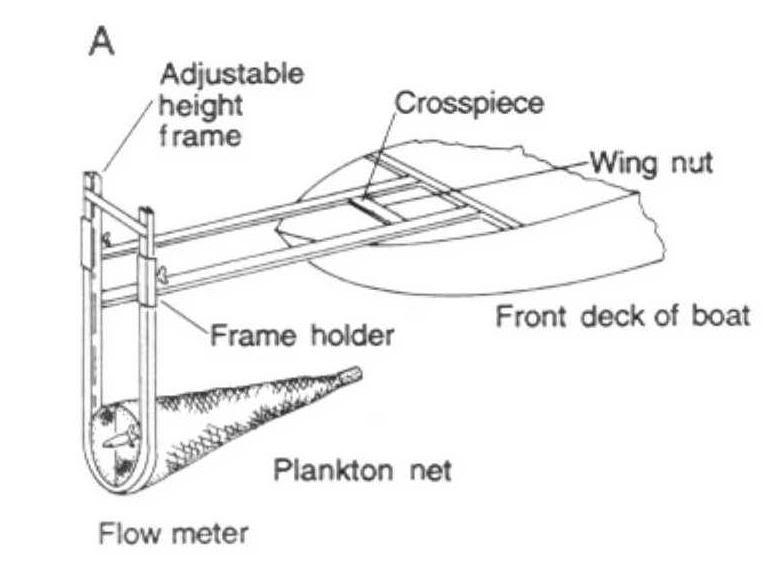

I am a fisheries science graduate student at Montana State University in Bozeman. I begin my field season on Ft. Peck Reservoir soon and recently decided that I’ll need to manufacture a “bongo net” and frame (conceptual figure below). Bongo nets/frames are relatively standard larval fisheries sampling equipment designed to be pushed by a boat at low speeds (< 1 mph). Standard they may be, frames for bongo nets are exceptionally expensive and my project’s budget will not support the purchase of one. I’ve decided that I’ll have to fashion one myself, but would like the thoughts and inputs of those who know more than I about engineering and handy work.

I should mention that the design in the image doesn't have to be exactly what I build. For example, the net end of the vertical frame does not have to be curved as it is in the image. I've provided only a conceptual design.

While the net I’m conceiving of does not look identical to the one in the figure, it is similar. I had originally considered using ¾” rigid conduit for both the horizontal and the vertical pieces but soon realized that the “adjustable height” part would be difficult to overcome. Granted, tack welding a small piece of 1” conduit (with set screw) onto the for end of the horizontal frame would allow for an adjustable vertical frame, but tack welds can fail, require specialized skills (which I do not have), and a completely self-repairable frame is ideal.

On my evening run, I realized that angle iron (the kind that is “perforated” every inch or so) may be perfect. The horizontal frame (including cross beams) could be easily attached to the bow—including an “extender” if necessary—and the vertical struts could be easily made to securely hold the net itself. Unfortunately though, I’m still up against the “adjustable height” problem, affixing the vertical piece to the horizontal frame, and (hopefully) being able to “hinge” the vertical piece so that it can fold back onto itself for ease of transport while on the water. (The hinge does not have to be an actual hinge; a bolt and cotter pin would be just fine.)

It would be nice if the hold apparatus were relatively durable (e.g., could be used for a few field seasons), but this is not necessary. It would also be nice if the entire thing could be disassembled for long-term storage. Permanently affixing the equipment to the boat is out of the question. Max depth of the net would likely be 10’ or maybe just a bit more. I will not have to change the depth of the net rapidly, but would have to do so while on the water. I will have a tool box on board, but using fasteners that could be manipulated by hand would be ideal.

If you have any questions, I’ll be happy to answer them. I would appreciate any thoughts you may have.

Thanks,

Steven Ranney

http://studentweb.montana.edu/steven.ranney" target="_blank" target="_blank" target="_blank

P.S. - If you'd like to communicate privately, feel free to send me a PM.

SR