I realize that many of us tuba players at one time or another play/played bass trombone, some of us also dabble with the contrabass trombone. Being all to familiar with the complexity of levers and linkage that is so common on our horns, both Bass trombone and tuba, I thought it would be fun to show one of the linkage conversions I recently did to a bass-bone in order to improve its mechanical function and make it a bit more comfortable to operate. Who knows maybe the improvement will help find it a new home.

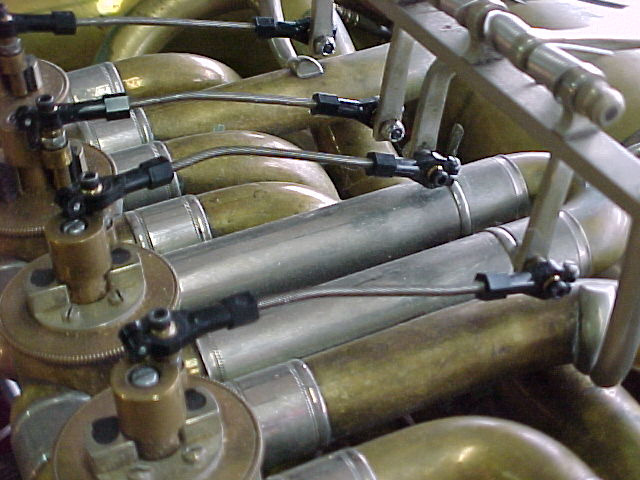

This is the duel rotor section of an Olds Bass that is probably about forty years old. The original linkage shown above is interesting (also heavy and noisey) but compared to what is currently available, it really sucked!

I scrapped the works and started over. Its dependent valve design made it a little tricky to work out but after racking my brains for an afternoon, I came up with something I thought would look cool and function as well as anything currently available.

I do not use that plastic RC car crap because I think it looks really stupid but thats just me. I know how some folks like Rick Denny enjoy working on there own instruments and thats great but having been trained in an "old school" way, I don't know how to make things any other way then to build it to last and make it like I mean it. Must be the German background in me, can't help it.

This forces me at times to do things the hard way, besides the connectors, all of the parts were made from scratch (bar and rod stock). The job took about one and a half very long days to perform all the machining, brazing and polishing prior to running it down to the local plate shop with another set of linkage I built for a Bach 50B.

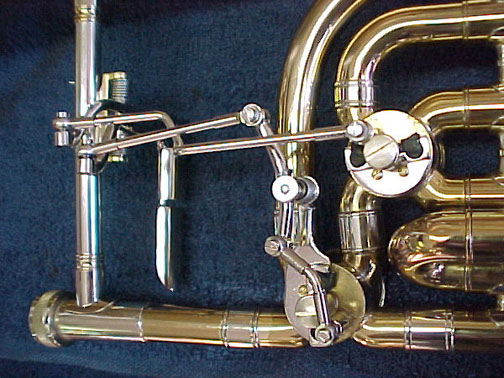

Shown above is the Bach after preassembly was completed. It also had a crap set of junk someone put on it after doing a rather interesting (not good) just interesting job of converting it from stacked dependent valves to in-line independent valves. Having made sure it works the way it should, it will be taken apart and prepared to be nickel plated with the other parts we have lined up.

The final product after nickel plating. I do about three of these type of jobs a year and try to keep it at that, no more. This is because even though they are a challenge and fun to do, they take me away from the other more profitable work waiting for me to tend to and after all this is my job. I love to see the interesting projects that get posted now and then on tubenet by other Technicians. Hope you find this post of interest and that it will stimulate some conversation.

Daniel C. Oberloh

Oberloh Woodwind and Brass Works

Saving the world, one horn at a time...