tubamirum wrote:NEVER sand a horn! Also, you can spray a horn without degreasing it by being very careful to wipe all traces of rouge with the softest cloth you can find (old flannel). Your job may not last as long but a sousaphone bell is going to get damaged before the lacquer darkens too much. Getting the wheel marks to disappear is tough and takes lots of practice. Don't do it an a humid day.

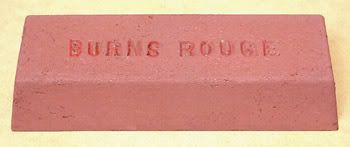

Man, you must be using a different rouge than what was pictured. That wax cake will absolutely screw up lacquer, and in my experience must be removed with a solvent.

While I agree a beginner should never touch sandpaper, how do you think the repair gods get that perfect smoothness? Tripoli will take off as much as sandpaper with enough time, and sandpaper saves time in careful hands. There's a reason Dan Oberloh copper-plates parts during a restoration--so he can sand most of that copper back off while still leaving brass.

That's why I have never wanted perfect smoothness in an overhaul--I'd rather keep the brass. But lots of folks want their overhauls to look new.

And the manufacturers? Bloke and I are convinced that the belt sander was the primary tool used in the Holton factory. That's not a compliment, but all tubas are sanded during manufacture to make them smooth.

Rick "who has piles of sandpaper in 1000 and 4000 grits" Denney

Its a little bar that says will provide a mirror like finish. We have the buffer. Just wondering how to use this stuff. Also..do you think this Nikolas gold tinted spray lacquer would be good for some old sousaphone bells?

Its a little bar that says will provide a mirror like finish. We have the buffer. Just wondering how to use this stuff. Also..do you think this Nikolas gold tinted spray lacquer would be good for some old sousaphone bells?  the bells are basically raw brass and have turned brown. We want to polish/buff these and lacquer them. Does anyone know how this might turn out?

the bells are basically raw brass and have turned brown. We want to polish/buff these and lacquer them. Does anyone know how this might turn out?